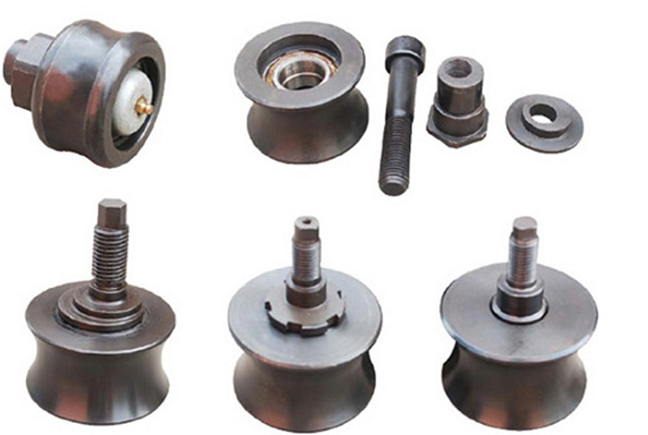

Guide/Double Roller For Construction Hoist

High precision guide rollers, customized according to buyer's drawings or samples.

1) Material Chrome steel ASTM52100, sometimes Stainless steel 440/304/316. Alloy steel ASTM5120 with carburizing is available.

2) High precision, P0, P6, P5.

3) Low noise

4) Long life.

5) Pre-lubricated and sealed.

| Material | Aluminum alloy,Brass,Stainless Steel,Carbon steel, according to customer's requirement |

| Finish | Milled /Tin plating, copper-plating,hot-dip galvanizing, black oxide coating,red anodized, black anodized,painting, powdering,rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Testing Equipment | CMM,Projector,Pull Tester,Automatic Optic Inspector,Projecting apparatus Salt Spray Test, Durometer, and Coating Analyzer,Tensile Machine |

| Management System | ISO9001:2008 |

| Certification | SGS,RoHS,Material Certication,PPAP |

| Production Capability | Auto-lathe turning:ODΦ0.5-20mm,Tol.±0.01mm CNC lathe turning:ODΦ0.5-250mm,Tol.±0.005mm CNC Milling:800x600mm(LxW),Tol.±0.05mm Grinding:Tol.±0.002mm Screw heading & rolling:Metric 0.8-M6,Unified Imperial#0-1/4'' Stamping:200T max |

| Lead Time | 5-15 working days |

| Samples | Welcome |

| Delivery term | By DHL,UPS,TNT,FedEx,EMS,By Ocean,By Air |

| Warranty | Replacement at all our cost for rejected products |

Available for a variety of sizes automation components,In-saiL provides solutions to suit any customer need.

Auto Lathe Turning

The single shaft cam-base automatic lathes are capable of massive production of brass, aluminum alloy, stainless,

steel components. Production range: O.D. 0.5-15.

CNC Milling 4-axis and 5-axis machining centers are capable of complex structural parts.

Production range: 800x600.

Screw Heading & Rolling

The screw production lines finish the cold heading and thread rolling for small carbon steel or stainless steel screws.

Production range: M0.8-M6 or equivalent sized imperial screws

Stamping machines perform the blanking, punching, blending, drawing. Currently we are working on simple stamping jobs.

Production range: 200T max.

We have powerful manufacturing capability, our automatic lathes, CNC lathes, CNC machining centers,

stamping machines and cold heading machines plus auxiliary,equipment like milling machine,grinding machine,

EDM and the cooperation of our partners, we are able to support every different components regardless of the prototyping

or series production.